Comprehensive Log Cabin Buying Guide: Avoid Costly Mistakes

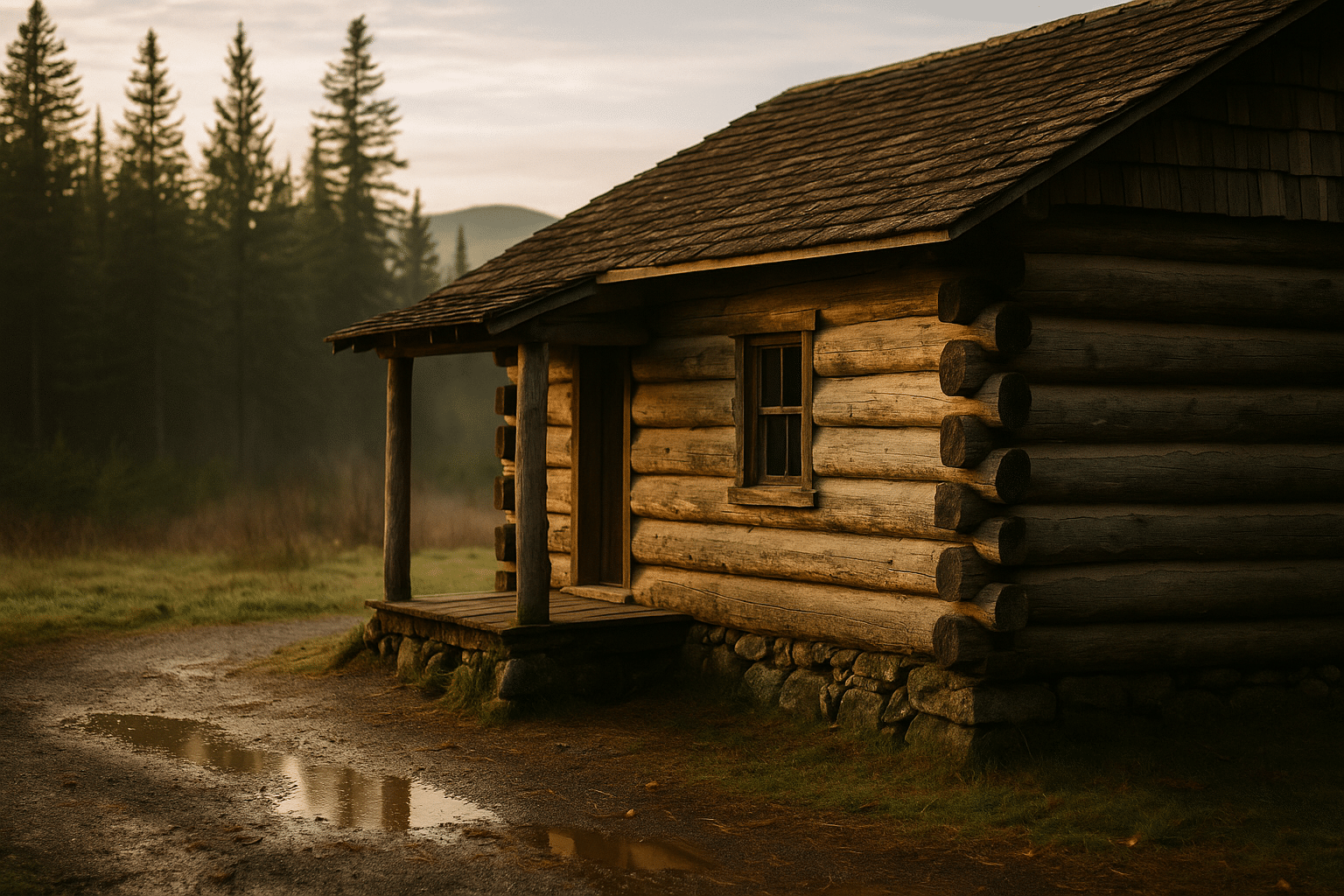

Why Log Cabins Captivate—and Why Getting the Buy Right Matters

Before falling for the warm glow of stacked logs and mountain air, it pays to map the path from idea to keys in hand. Buying a log cabin is not just a style decision; it’s an investment that blends structure, energy performance, maintenance, and lifestyle. The most common regrets come from avoidable gaps: underestimating site prep, overlooking code requirements, misreading kit specifications, and skipping contingency funds. Start with a clear plan, and the dream remains a dream—without becoming a spreadsheet nightmare.

Outline of this guide:

– What to weigh before you buy: goals, climate, and timeline

– Site, design, and energy strategy: orientation, foundations, insulation, and moisture

– Materials and build methods: log species, profiles, joinery, kits vs. turnkey

– Budget, financing, and total cost of ownership: realistic ranges and hidden line items

– Permits, contracts, delivery, and upkeep: paperwork, warranties, and maintenance rhythm

First, anchor your goals. Are you seeking a weekend retreat, a short-term rental, or a full-time residence? Each use case drives different sizing, durability, and code expectations. For example, a rental property may prioritize low-maintenance finishes and easy winterization, while a full-time cabin in a snowy region needs proven roof loads, snow-shed detailing, and reliable energy performance. Think through:

– Occupancy: seasonal vs. year-round

– Size and layout: compact footprint vs. multi-wing design

– Climate realities: freeze-thaw cycles, wildfire risk, humidity, and wind exposure

– Build timeline: off-season discounts vs. weather delays

– Access: road restrictions for delivery trucks, crane locations, and utility tie-ins

Next, learn the language of log construction so you can compare apples to apples. “Log cabin” can mean milled log kits, handcrafted scribed builds, timber hybrids, or insulated log-look systems. Each option handles movement, sealing, and maintenance differently. A thoughtful buyer looks beyond the catalog photo to standards, moisture content, joinery, and warranties. This guide focuses on practical, evidence-based choices—what matters for decades, not just the day you get the keys.

Site, Design, and Energy Strategy: Where Performance Really Begins

Great cabins are placed, not just built. Your site governs drainage, wind, solar gain, and access—variables that determine comfort and cost more than many upgrades. Begin with a topographic look: where does water flow in heavy rain? A log shell is sturdy, but standing water and splashback rot trim, stain finishes, and compromise sills. Aim for positive drainage away from the foundation, wide roof overhangs, and ground clearances recommended by local codes. On steep lots, consider stepped foundations or piers that reduce excavation and help keep moisture under control.

Orientation is free performance. South-facing glazing (in colder regions) can capture winter sun, while shaded west elevations reduce summer overheating. Deep overhangs, porches, and exterior shades are traditional cabin features that double as passive design tools. In wildfire-prone zones, choose defensible space landscaping, metal or treated roof assemblies, screened vents, and non-combustible zones around the perimeter. In windy areas, a lower, compact plan with bracing and secured roof decks keeps the structure calm in storms.

Energy performance in log construction is nuanced. Solid wood has lower nominal R-value per inch than modern foam or dense-pack assemblies, but the mass of logs smooths temperature swings when the envelope is well sealed. The biggest win is air sealing: studies commonly estimate air leakage can account for a significant slice of heating and cooling use. Look for systems that address:

– Air sealing: gaskets, splines, and continuous sealant lines at horizontal courses

– Movement: settlement allowances above windows and doors

– Thermal bridges: insulated headers, sill plates, and rim details

– Roof insulation: many cabins place most R-value in roof assemblies, not walls

Foundation choices affect comfort and cost. Options include pier-and-beam for sloped sites, crawl spaces for service access, and insulated slabs for simplicity and radiant heat potential. In cold climates, footings must reach below frost depth; in wet climates, capillary breaks, perimeter drains, and vapor barriers are non-negotiable. Think of the site/design package as your silent insurer: a well-chosen orientation, robust roof details, and meticulous drainage can save more over time than marginal upgrades elsewhere.

Materials and Construction Methods: Logs, Joinery, and Kits Explained

Not all logs—or log systems—behave the same. Species vary in density, natural rot resistance, and appearance. Common choices include pine, spruce, fir, cedar, and larch, each bringing distinct grain, color, and durability profiles. For example, cedar is often valued for natural resistance to decay and insects, while denser spruces and firs can deliver strong structural performance. Moisture content matters as much as species. “Green” logs may be more economical upfront but shrink more as they dry. Kiln-dried or engineered laminated logs cost more but are dimensionally stable, helping gaskets and finishes last longer.

Profiles and joinery define both look and longevity. Milled D-logs, round logs, square dovetail profiles, and handcrafted scribed logs create different shadow lines and settle differently. Corner systems include saddle-notch and dovetail; both can perform well when cut precisely and sealed with quality gaskets and chinking or scribe-fit methods. Pay attention to:

– Sealing strategy: compressible gaskets and tapes at each course

– Settlement details: through-bolts, slip joints, and adjustable jacks at posts

– Window/door bucks: insulated bucks that allow movement without leaks

– Chinking vs. scribe-fit: chinking enables maintenance access; scribe-fit relies on precision

Kits vs. turnkey builds is a key decision. Kits often include the log shell, fastening hardware, basic gaskets, and plans. Some offer pre-cut, numbered logs to speed assembly; others require on-site cutting by an experienced crew. “Shell-only” packages leave roofing, insulation, windows, doors, electrical, and finishes to you and your contractor. Turnkey contracts deliver move-in readiness, but costs vary with finish quality, site conditions, and regional labor rates. A hybrid approach—kit shell with local trades—can balance control and cost if you have a reliable general contractor.

Don’t overlook the roof and envelope beyond the logs. Many cabins use vented or unvented “hot” roofs with high-R insulation above the deck, robust underlayments, ice-dam protection at eaves, and durable finishes such as metal or heavy shingles. Large overhangs protect walls from UV and rain, reducing finish cycles. Finishes themselves should match exposure: semi-transparent stains showcase grain but typically require more frequent re-coats than solid-color finishes. Ask vendors for maintenance schedules aligned with your climate and UV index.

Costs, Financing, and the Real Budget: From Kit Price to Keys

Sticker prices can be misleading. A kit quote might sound accessible, but the total project budget includes site prep, foundation, utilities, roofing, windows, doors, interior finishes, mechanical systems, permits, delivery, and contingencies. In many regions, shell-only kits can land in a range that varies widely by species, thickness, and profile. Fully finished, move-in-ready cabins often fall into ranges comparable to custom homes, especially with complex roofs, high snow loads, or remote access. Treat any national average cautiously; local labor and hauling can swing totals dramatically.

Plan a realistic budget structure:

– Site and access: driveway, clearing, excavation, erosion control

– Foundation: footings, walls or piers, drains, vapor barriers

– Shell: log package, fasteners, gaskets, erection crew

– Roof and envelope: insulation, underlayments, roofing, overhangs

– Openings and finishes: windows, doors, flooring, cabinets, fixtures

– MEP systems: electrical, plumbing, HVAC, septic/well or utility hookups

– Soft costs: engineering, permits, surveys, impact fees, inspections

– Logistics: delivery, crane time, staging, weather protection

– Contingency: often 10–15% for unknowns

Financing can be different from a standard suburban build. Lenders may offer construction-to-permanent loans, releasing funds in stages (“draws”) as work progresses and inspections pass. Appraisals for unique rural properties can be conservative; provide detailed plans, specifications, and a credible contractor bid to strengthen the case. Factor interest carry during construction into your cash flow. Insurance during the build (builder’s risk) and after completion may cost more in wildfire or wind zones, so get quotes early and design accordingly to reduce premiums where possible.

One practical exercise: create two budgets. The first is your expected build path with chosen finishes. The second is a “resilience plan” that caps unknowns by pre-selecting alternates—simpler roof forms, standard window sizes, durable but moderately priced flooring, and streamlined kitchen layouts. This approach keeps the feel you want while shielding the project from supply spikes or weather delays. Most overruns trace to scope creep or site surprises; a transparent budget plus early geotechnical and survey work keeps both under control.

Permits, Contracts, Delivery, and Aftercare: Keeping Surprises in Check

Permits for log cabins follow the same fundamentals as any dwelling: zoning, setbacks, structural compliance, energy code, and environmental rules. Some jurisdictions have log-specific provisions or require engineering stamps for certain wall heights and roof spans. Energy codes may include pathways tailored to solid wood walls, which recognize mass effects while still demanding proven air sealing and robust roof insulation. In rural areas, add septic permits, well tests, driveway approvals, and fire department access. If there’s a homeowners association, confirm exterior rules on colors, roof materials, and outbuildings before you buy.

Contracts are where the dream becomes a plan. Seek clear scope definitions, line-item allowances, a draw schedule tied to milestones, and documented standards (fasteners, gaskets, moisture content ranges, settlement details). Ask for:

– Submittals: shop drawings, species certifications, and fastener specs

– Tolerances: settlement expectations and adjustment procedures

– Weather plans: protections for stacked materials, temporary roofing, and dry-in deadlines

– Warranty terms: coverage for air leaks, water intrusion, and structural issues

– Dispute resolution: defined steps, timelines, and responsible parties

Delivery and logistics deserve their own checklist. Long trucks need turning radii and stable staging pads near the crane. Materials should be stickered and covered, but ventilated to avoid condensation. Schedule dry-in as soon as possible after shell assembly; exposed log tops can stain or check if soaked and dried repeatedly. Capture photos of details (gaskets, bucks, flashing) prior to concealment—your future self will appreciate the documentation when inspecting or troubleshooting years later.

Aftercare is predictable when you plan it. Logs move subtly with seasons; tensioning hardware and adjustable posts should be checked per manufacturer guidance during the first year, then annually. Finishes typically need re-coating on sun-exposed elevations more frequently than on shaded sides. Keep vegetation and sprinklers away from walls, maintain gutters and ground slope, and inspect for small sealant failures before they grow.

Conclusion for Buyers

You don’t need luck to buy a great log cabin—you need a framework. Match the site to the design, insist on documented sealing and settlement details, price the full project instead of the shell alone, and lock logistics and maintenance into your plan. Do this, and you’ll step across the threshold of a cabin that’s not only charming on day one, but also comfortable, efficient, and resilient for the long haul.