PVC Window Buying Guide

Outline and How to Use This PVC Window Buying Guide

Before diving into details, it helps to see the map. PVC windows sit at the intersection of comfort, energy performance, durability, and aesthetics, and the choices you make ripple through daily life for decades. This outline previews the path and explains how to apply the information to your home or project. You can read end-to-end for a comprehensive view or scan each heading and jump where needed. The goal is practical clarity: fewer surprises, smarter trade‑offs, and a window package that suits your climate, budget, and style without overcomplication.

Here is the structure we will follow, along with how each part helps your decision:

– Materials and frame construction: what PVC is, how multi‑chamber profiles work, and how it compares to wood, aluminum, and composite.

– Glazing and energy performance: double vs triple panes, low‑e coatings, gas fills, spacers, and how to read U‑factor, SHGC, VT, and air‑leakage ratings.

– Hardware, security, and ventilation: operable types, sealing differences, multipoint locking, child safety features, and airflow options.

– Installation, costs, maintenance, and lifespan: retrofit vs full‑frame, flashing basics, total cost of ownership, care routines, and recycling considerations.

– A concise conclusion with checklists you can bring to a showroom or share with an installer.

How to use this guide effectively:

– Start with your climate and goals: prioritize thermal performance in cold regions, solar control in hot sun, and sound reduction near busy streets.

– Set a realistic budget range and add a buffer for accessories such as screens, trickle vents, or laminated glass in vulnerable rooms.

– Match operation types to rooms: generous ventilation in kitchens, secure overnight airing in bedrooms, wide clear openings for egress where required.

– Keep installation quality in view; even premium components underperform if flashing, shimming, and sealing are sloppy.

As you read, capture a simple shortlist: preferred frame color, opening types per room, target U‑factor/SHGC, desired glass options (laminated, tempered, or both), and any accessibility or safety needs. That short list becomes your conversation starter with retailers and installers. It also keeps you from being swayed by showroom shine and helps you compare like‑for‑like quotes with confidence.

Materials and Frame Construction: Why PVC and How It Compares

PVC frames are popular for their combination of insulation, low maintenance, and design flexibility. The core idea is simple: extruded profiles with multiple internal chambers slow heat transfer and stiffen the frame, while gaskets and glazing beads create tight seals against air and water. Compared with metals, PVC’s thermal conductivity is far lower, which means the frame itself contributes less to heat loss. Multi‑chamber designs, sometimes paired with foam inserts or internal reinforcement, further reduce conduction and improve stiffness where spans are long or wind loads are high.

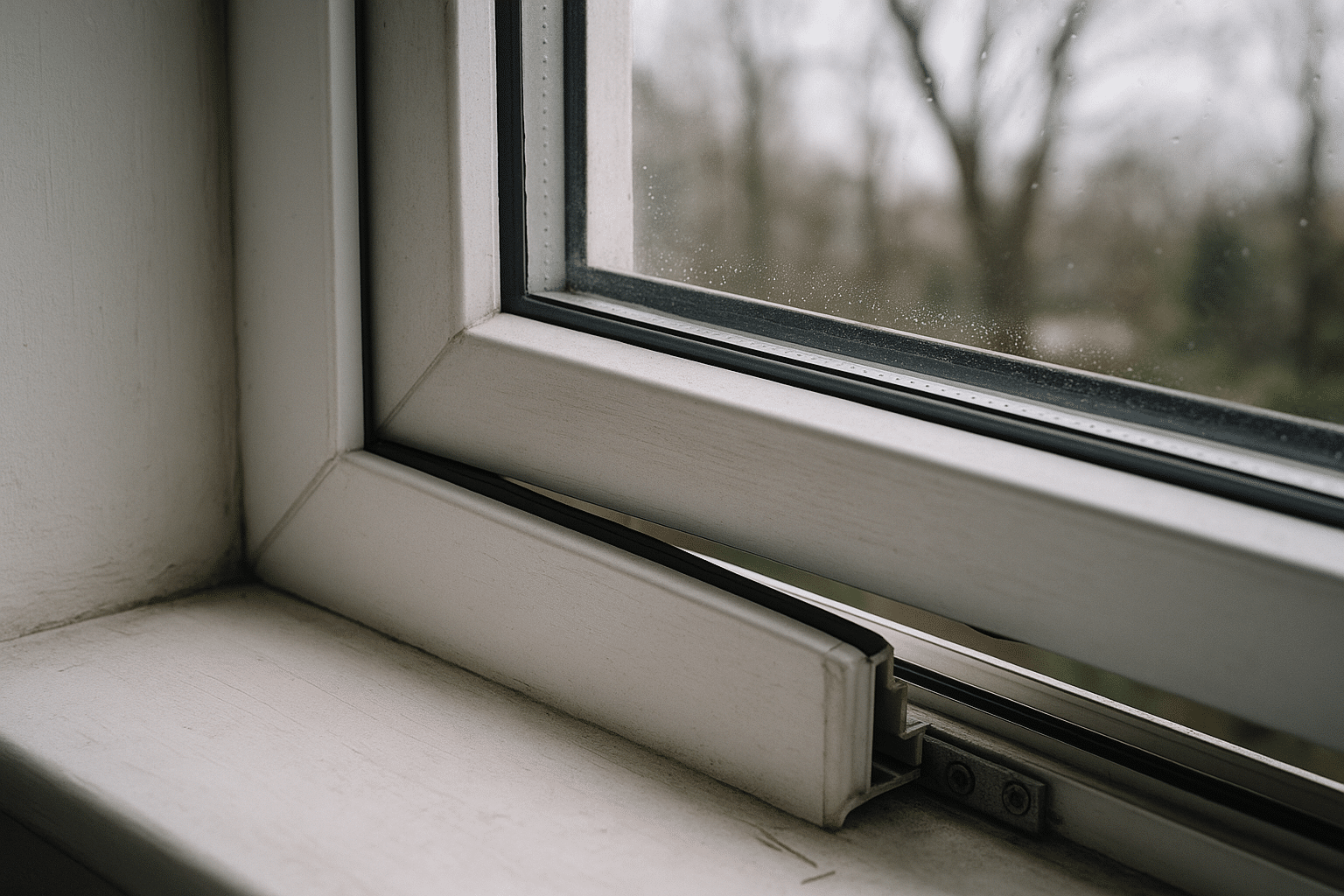

Construction details matter. Corners are typically heat‑welded for monolithic joints that resist racking and water intrusion. Co‑extruded or replaceable gaskets (often EPDM or similar) provide resilient compression seals. Reinforcement options vary: galvanized steel is common, while some profiles use composite or fiberglass elements to limit thermal bridging. Surface finishes range from smooth white to textured foils that mimic timber grains or darker hues; modern capstocks improve UV stability so color holds without frequent repainting.

How does PVC compare with the usual alternatives?

– Wood: warm look and good insulation, but needs periodic painting or staining, and can swell without careful detailing. PVC offers similar thermal performance with notably less upkeep.

– Aluminum: slim sightlines and structural strength, especially for large spans, but requires advanced thermal breaks to approach the insulation of PVC. Without them, frames can feel cold to the touch and may condense in humid rooms.

– Composite/fiber‑reinforced: very stable and durable with refined aesthetics, generally priced above PVC. For many homes, PVC delivers a compelling cost‑to‑performance ratio.

Thermal and structural realities shape expectations. Coefficients of thermal expansion are higher for PVC than for aluminum or wood, which is why correct shimming and expansion allowances at installation are essential. Properly reinforced profiles easily meet typical residential wind and structural loads, provided spans are appropriate and hardware is sized correctly. Fire behavior is regulated by local codes, and glazing choices like tempered or laminated safety glass are often required in bathrooms or near floor‑level openings. With contemporary stabilizers and additives, PVC frames resist yellowing and brittleness, and many suppliers offer recycling pathways for offcuts and old frames, supporting circular use of materials. These practical qualities explain why PVC has become a well‑regarded option for both replacements and new builds.

Glazing and Energy Performance: Reading the Numbers That Matter

The glass unit is the engine of a window’s energy performance. Double‑pane insulated glass with a low‑emissivity coating and argon fill is a common baseline that balances clarity, cost, and efficiency. Triple‑pane units push performance further, often using two low‑e coatings and inert gas to reduce heat loss in cold climates. Warm‑edge spacers improve the temperature at the glass edge, cutting down the chilly perimeter band that can invite condensation on winter mornings. Laminated interlayers can add both security and sound control with minimal visual trade‑offs.

Energy labels condense complex physics into a few metrics:

– U‑factor: lower is better for reducing heat transfer. Many code‑compliant PVC window packages land around U‑0.30 (Imperial units) or roughly 1.6 W/m²·K (Metric), while higher‑performing triples may reach lower values depending on configuration.

– Solar Heat Gain Coefficient (SHGC): measures how much solar radiation passes through. In hot, sunny regions, lower SHGC helps keep cooling loads in check; in cold or mixed climates, moderate SHGC on south‑facing windows can welcome passive heat in winter.

– Visible Transmittance (VT): indicates daylight. High VT keeps interiors bright, but extremely low SHGC coatings can reduce VT slightly; balance depends on glare tolerance and room use.

– Air Leakage (AL): shows how drafty a unit is under test conditions. Compression‑seal designs often post tighter AL ratings than sliding designs when installed correctly.

Acoustics matter more than many buyers expect. Typical double‑pane units fall in the STC high‑20s to low‑30s; adding laminated glass or unequal pane thickness can move results into the mid‑30s or higher, which is noticeable near traffic or flight paths. For bedrooms or home offices, this can be the difference between faint noise and restful quiet. If street sound is a concern, ask for data on STC and OITC, and specify laminated makeups in the loudest rooms.

Practical, climate‑aware choices:

– Cold climates: prioritize low U‑factor and consider triple glazing on large windows, especially on north and east elevations.

– Hot climates: aim for low SHGC, consider spectrally selective coatings that block heat while maintaining view, and pair with shading like overhangs or exterior blinds.

– Mixed climates: choose region‑appropriate U‑factor and a moderate SHGC, and vary glazing by orientation if budget allows.

Remember that frame design, spacers, and installation influence the real‑world outcome as much as the glass recipe. A window with excellent center‑of‑glass performance can still underperform if the frame is leaky or the perimeter seal is poorly executed. Compare whole‑unit ratings, not just glass center values, and verify that ratings reflect the exact size and configuration you plan to buy.

Hardware, Security, and Ventilation: Daily Use and Peace of Mind

Windows serve daily life, not just energy models, and that is where hardware, operation type, and ventilation features shine. Casements swing on side hinges and lock against compression seals, offering low air leakage and excellent wind performance. Tilt‑and‑turn units provide two modes in one: a secure top tilt for gentle ventilation and a full turn for wide egress and easy cleaning. Sliders save space and suit wide openings but rely on sliding seals that are typically slightly leakier than compression types. Fixed lights offer the cleanest sightlines and highest energy performance where no ventilation is needed.

Hardware choices shape durability and safety. Multipoint locks distribute pressure around the sash, improving gasket compression and deterring forced entry. Robust hinges rated for the sash size keep alignment true over time; look for corrosion‑resistant finishes in coastal or humid zones. Night‑latch or micro‑ventilation positions allow a small, secure opening for fresh air without inviting a draft. Internal glazing beads add tamper resistance, and laminated glass in at‑risk areas elevates protection without metal bars.

Ventilation strategy is about comfort and indoor air quality. Trickle vents provide continuous background airflow and can help manage humidity in tight homes, while tilt positions or partial casement openings enable faster air changes when cooking or showering. Pairing room‑by‑room operation types pays off: a quiet tilt option in bedrooms, a sturdy casement in kitchens to purge steam, a large slider where a deck needs an uninterrupted pass‑through.

Practical details to check in person:

– Handle ergonomics: easy grip for all ages and abilities, with lever motion that does not foul blinds.

– Sash weight and smoothness: balanced action without shudder or binding, indicating proper reinforcement and hardware sizing.

– Gasket continuity: uninterrupted seals at corners, with firm compression when locked.

– Security features: laminated glass where required, reinforced strike plates, and hinge‑side security pins on outward‑opening units.

For insect‑prone regions, integrated screens that remove easily for cleaning are a small joy. In multi‑story homes, tilt‑in cleaning modes can spare ladders and risky maneuvers. Thoughtful hardware and operation types make everyday life quieter, safer, and simpler—benefits you feel long after the installer leaves.

Installation, Costs, Maintenance, and Lifespan: Bringing It All Together

Even outstanding components cannot rescue a poor installation. Accurate measurement comes first, with allowances for frame expansion and squareness of the opening. In retrofits, choose between insert replacement (leaving existing frames in place) and full‑frame replacement (down to the rough opening). Insert jobs are faster and less invasive but can reduce glass area slightly; full‑frame projects restore original daylight and allow comprehensive flashing. A robust method includes a sloped sill or pan, self‑adhered flashing tapes shingled correctly, solid shimming at lock points, low‑expansion foam or backer rod, and a weather‑resistant sealant joint sized to move without tearing.

Common pitfalls to avoid:

– Skipping a sill pan or slope, which invites hidden leaks and long‑term damage.

– Over‑foaming the perimeter, warping frames and compromising operation.

– Neglecting head flashing and properly layered tapes, leading to water intrusion during wind‑driven rain.

– Forgetting weep paths and blocking drainage with sealant.

Costs vary by region, labor rates, size, glazing package, and accessories. As a general pattern, PVC sits in a lower‑to‑mid price tier relative to composite units and many thermally broken metal systems, while offering strong energy performance. Adders can include laminated glass for noise or security, specialty colors, warm‑edge spacers, upgraded hardware, and integrated blinds. Evaluate total cost of ownership: cleaning is minimal, repainting is unnecessary, and energy savings can accumulate season after season, particularly in climates with high heating or cooling demand.

Care is simple. Wash frames and glass with mild soap and soft cloths; avoid abrasive pads or harsh solvents that can dull finishes. Inspect gaskets and drainage slots annually, clearing debris so water exits as designed. Lubricate moving hardware sparingly and check sash alignment; small adjustments keep locks engaging crisply for years. With quality materials and routine attention, service life commonly reaches multiple decades, especially where UV exposure is managed by overhangs or thoughtful orientation.

Conclusion and next steps:

– Define priorities by room: energy, noise, ventilation, view, or security.

– Note target ratings: whole‑unit U‑factor, SHGC by orientation, and desired STC in noisy rooms.

– Choose operation types that fit the space and use pattern, not just showroom appeal.

– Insist on documented installation steps: sill pan, shingled flashing, shims, and expansion joints.

– Compare like‑for‑like quotes with a simple checklist, and ask for written performance data for the exact sizes you plan to purchase.

PVC windows can be an outstanding balance of performance, comfort, and practicality when specified and installed with intention. With the ideas in this guide, you can navigate choices with ease, align features to your climate and lifestyle, and invest in windows that quietly improve every day at home.